VAC E-mail List Archive

The Vintage Airstream E-mail List

Archive Files

[Date Prev][Date Next][Thread Prev][Thread Next][Date Index][Thread Index]

[VAC] Re: what brand of tire is good?

Hi All,

I don't get it about "front plate" protection and front plate separation

that can be the result of using radial tires vs.. bias ply.

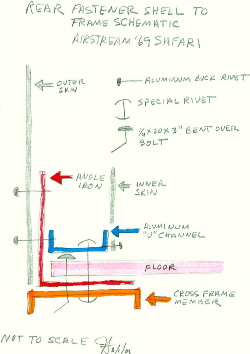

The only thing that I can imagine that could cause the front plate to

separate from the frame is flexing of the "A" frame with the pivot point

located well behind the front plate. This assumes that the plate is the

angle iron that extends about 9 inches up behind the outer skin and has a

double row of rivets to bond it to the skin. The foot of the angle iron

extends about an inch under the floor, inside the aluminum "U" channel that

secures the upper structure to the floor/frame with rivets and bolts. (see

small attached sketch)

I can imagine that the reason for the separation does not have anything to

do with tires or the equalizer hitch assembly. I've noted severe corrosion

(rust) of the washers that secure the rivet heads (both top and bottom) that

bind the upper body to the frame. I recall that there are 5 rivets.

Additionally, there are about five 1/4 X 20 X 3 inch bolts that secure the

floor to the frame in the same vicinity. The ten bolts/rivets pass through

the foot of the angle iron that may be the referenced "front plate". If

this the point of separation, the flex may contribute, but the root of the

problem is failure of the fasteners from corrosion.

I've noticed a similar problem with pop-type rivets where the pull stem is

steel in an aluminum rivet. The corrosion eventually causes the rivet to

fail (these hold the trim strip and banana curve and most of the belly pan).

I have NOT noticed any deterioration of the "buck-type" rivets that are used

through out the A/S to fasten aluminum to aluminum. However, the vertical

section of the angle IRON is riveted to the aluminum skin with aluminum

rivets. It's possible that electrolysis could compromise the double row of

rivets.

It seems that the specific point of separation must be identified. Either

the vertical plate or the foot under the floor. It's logical that once the

fasteners are weakened in either location, the soft aluminum would

eventually fail. Same seems true for the rivets that bind the aluminum "U"

channel to the floor/frame. If the rivets through the foot of the angle

iron are compromised by corrosion, it is most assured that the floor is

rotted and soft. This would allow the foot to move and eventually cause

failure of the rivets.

All this said, it's strictly my opinion that tires and flexing of the "A"

frame may contribute to separation of the "plate" (assuming I've properly

identified what the plate is); however, the cause is corrosion from water

where it shouldn't be. To me, this makes caulking of the banana curve seam

under the trim strip and other seams around the "A" frame cutouts a critical

owner maintenance task. Much like maintenance caulking roof openings.

I noted the severe corrosion of these fasteners in both the front and rear

of my '69 Safari when I opened the inner skin to replace sections of

flooring. Associated with this corrosion was near total disintegration of

the floor pinched between the frame/angle iron/aluminum "U" channel.

It seems that once the rivets/fasteners are compromised, protecting the

"plate" by taking it easy only delays a future catastrophe. My choice is to

be sure the fasteners are not subjected to the elements that cause corrosion

and floor rot. I would advise A/S restorers to pay particular attention to

these fasteners.

The small sketch is attached to show the rear connection; however, it is

nearly identical to the front connection and might help visualize what I

tried to describe.

Joy