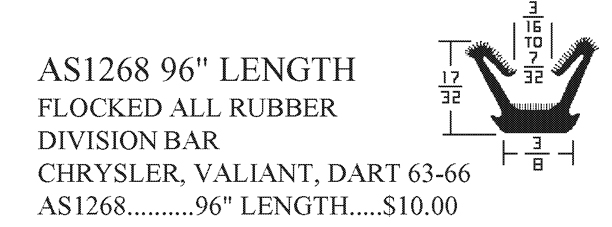

- The rubber which will fit the windshields can be seen on the CR Laurence Co website, Catalogue number AV4688 as detailed below:

CRL Early Model Chrysler Weatherstrips for 3/16" to 1/4" Back Glass

- OEM Quality

- Early Chrysler Models

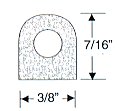

CRL Weatherstrip for Older Model Ford and Mercury fits 3/16 to 1/4 inch (4.8 to 6.4

millimeter) rear window glass. CRL Weatherstrips are manufactured to OEM

specifications. These rubber weatherstrips are easy to replace, and offer a watertight

seal using one of the following CRL Automotive Sealants: CRL7708 Flow Grade Non-Curing Butyl or CRL7711 Flow Grade Butyl that cures to a butyl tape consistency.Use CRL958 CRL Quick Release Agent or 3M8971 3M Release Agent to soften the adhesive for quick removal of old sealants and weatherstrips. Clean up excessive adhesives with our CRL2032 General Purpose Solvent and Adhesive Cleaner.

- OEM Quality